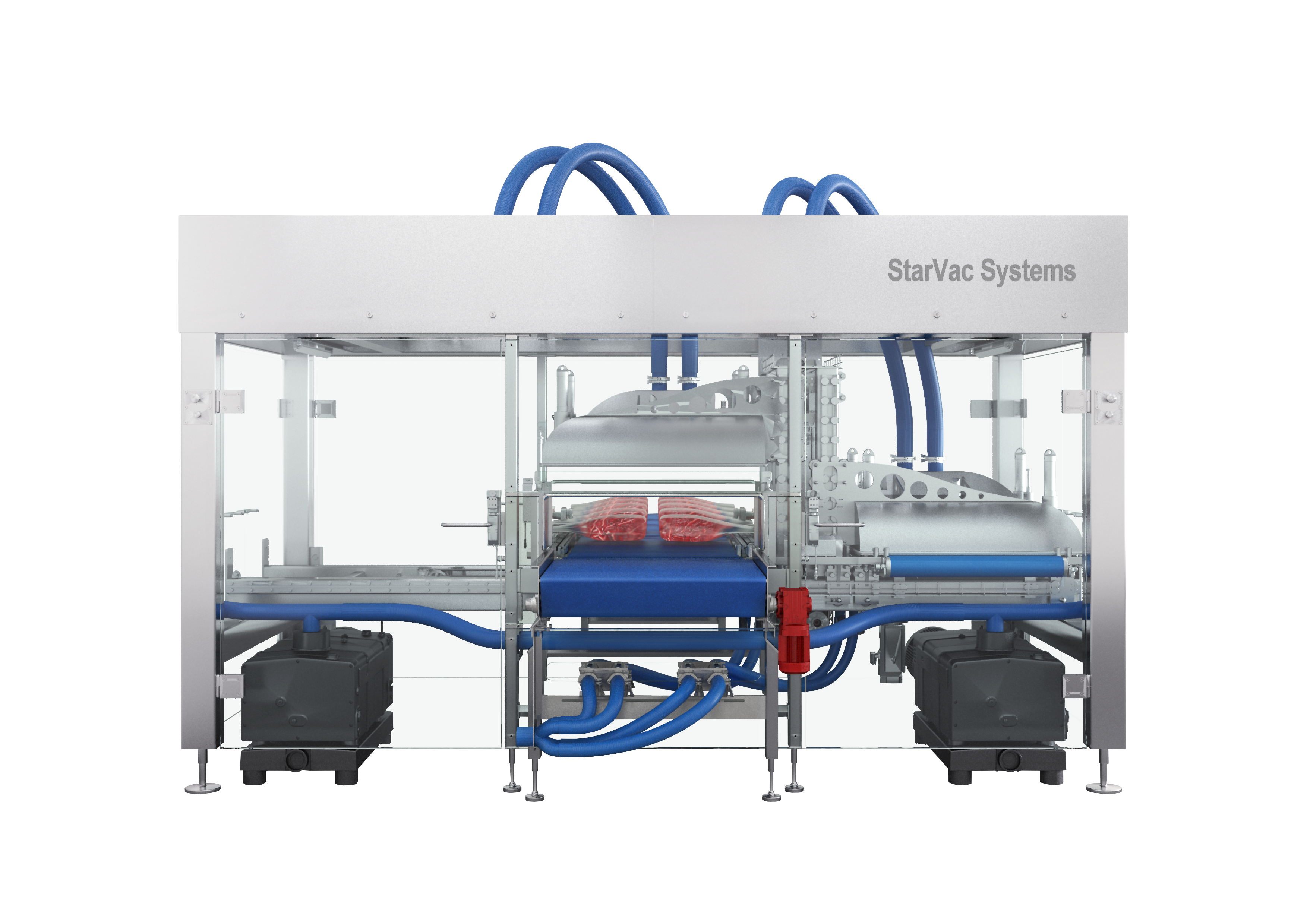

Automated VACUUM PACKAGING

StarVac Systems

StarVac Systems is a leading and innovative manufacturer of vacuum packaging machines for the red meat, cheese, smallgoods and pet food industries. Our focus is on the development and manufacture of highly automated and efficient technology to provide customers with peak performance and high returns on their investment.

Our packaging machines, in combination with our automated loading system, shrink tunnels and driers, represent the ideal solution for your automated packaging line.

Being close to our customers is a key value for StarVac Systems. Therefore, StarVac Systems is represented by own sales companies and representatives around the world.

Jupiter 445 Advantages

- High packaging speed

- Small footprint

- Low energy consumption

- Environmentally friendly

- Best in show

Contact us for your vacuum packaging needs

Product Video jupiter 445

Corporate News

Appointment of Australian Service Technician

Ferraro invests in Saccardo Vacuum Packing

StarVac team scaling new heights

Meat Processing

StarVac offers various sizes and automation levels for the vacuum packing red meat products like lamb and beef. We also offer complete automated packing lines for this industry.

Smallgoods packaging

StarVac offers various sizes of automatic chamber belt machines for the vacuum packing of smallgoods, inclusive shrink tunnels and dryers.

Seafoods Packaging

StarVac offers various sizes of automatic chamber belt machines for the vacuum packing of seafood, inclusive shrink tunnels and dryers.

Cheese packaging

StarVac offers various sizes of automatic chamber belt machines for the vacuum packing of cheese. We also offer complete automatic packing lines for cheese block processing.